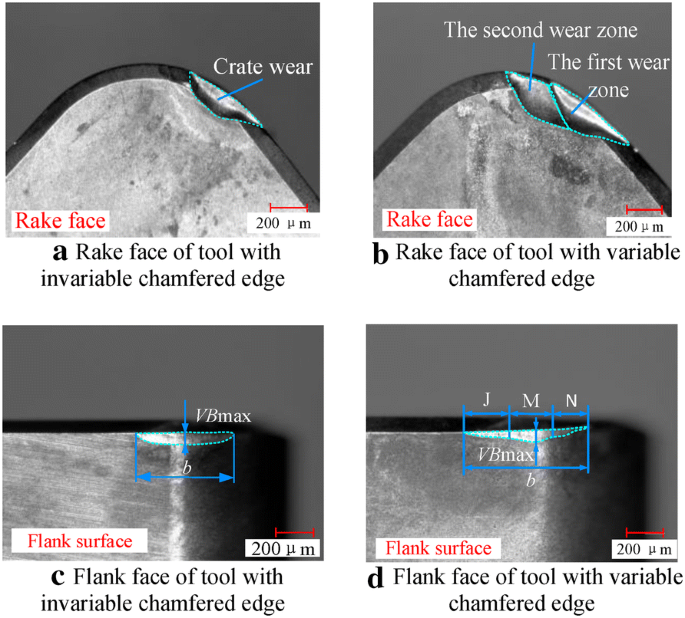

Experimental Study on Wear Characteristics of PCBN Tool with Variable Chamfered Edge | Chinese Journal of Mechanical Engineering | Full Text

Infinity MFG - Tool wear describes the gradual failure of cutting tools due to regular operation. It is a term often associated with tipped tools, tool bits, or drill bits that are

The effect of inclusion composition on tool wear in hard part turning using PCBN cutting tools - ScienceDirect

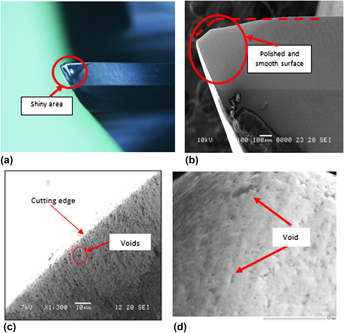

Study on wear mechanism of solid carbide cutting tool in milling CFRP | Journal of Materials Research | Cambridge Core

CBN Cutting Tools Wear Type and improved methods_Company News_News_Halnn superhard materials Co.,Ltd

Effect of cutting edge modification on the tool flank wear in ultrasonically assisted turning of hardened steel - Masoud Farahnakian, Mohamad Ebrahim Keshavarz, Sadegh Elhami, Mohammad Reza Razfar, 2019

Figure 7 from Evaluation of tool life - tool wear in milling of Inconel 718 superalloy and the investigation of effects of cutting parameters on surface roughness with Taguchi method | Semantic Scholar

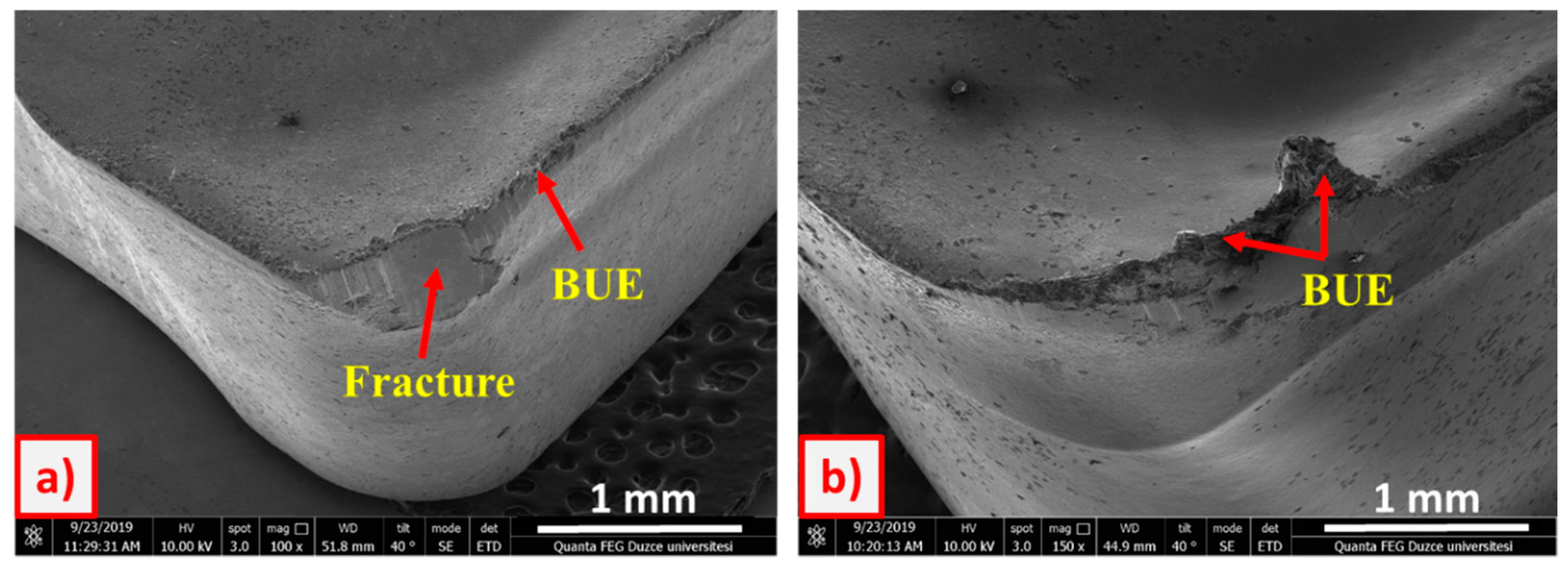

Experimental Investigation on Tool Wear in AISI H13 Die Steel Turning Using RSM and ANN Methods | SpringerLink

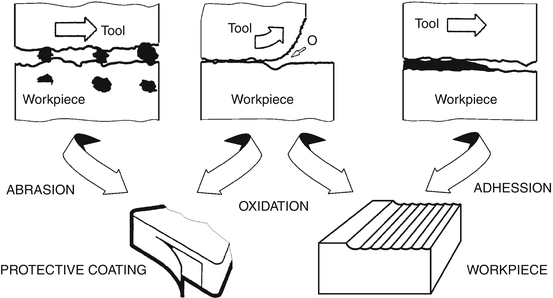

![PDF] Wear mechanisms of cutting tools in high-speed cutting processes | Semantic Scholar PDF] Wear mechanisms of cutting tools in high-speed cutting processes | Semantic Scholar](https://d3i71xaburhd42.cloudfront.net/583d65b08be770f5d8c698e2d32542524add2dd4/7-Figure8-1.png)